You’re an operator with responsibility for two or more offshore wind farms. Every day, you have maintenance tasks to complete involving numerous contractors and vessels. You also need to have minute-by-minute weather and wave information and it’s a constantly changing picture. You need to know that the people coming to your site have the right qualifications and are made aware of any restrictions that are affecting the locations they need to work on. You need to be able to plan shifts accurately and you need full visibility of what’s happening on site at any one time.

All this is a headache, even with just one wind farm to manage. Multiply the number of turbines and sites, and it becomes almost unmanageable when this is done with spreadsheets or other manual methods. There are so many opportunities for error – perhaps a contractor turns up with an out-of-date qualification but this is only detected once they are out on the vessel. A team might transfer onto a turbine only then to find out the tower ladder inspection has expired. A vessel approaches a location only then realising the turbine already has a team working there. And it’s incredibly inefficient with perhaps six to eight full-time control room staff salaries needed to cover the hour-by-hour management of O&M tasks.

This is essentially why Sennen was created. We could see that the growth of the industry was out-pacing the systems available to support operators. We set about creating a fully centralised digital control room that would allow just a few people to run multiple sites from one location. We call it our “Super Control Room”. It’s the depth and breadth of what our system offers, plus the number of data sources we integrate with, that takes it far beyond a simple management tool.

Planning offshore activities involves complex logistics. This requires a high level of digital intuition for work to be automated successfully. Operators using Sennen are able to build reliable and effective work plans with minimum hassle – problems are identified automatically at the planning stage and resolved by the contractor before you even hear about them. You can manage a daily schedule of wind turbine visits with detailed shift plans that can be adapted as circumstances and weather change throughout the day.

Mike Young, senior consultant at Sennen, used the software when he worked at London Array as operations manager, and has first-hand experience of how it transforms the working day.

One of the things that are really clever about the system is that it pulls all the data relating to the wind farm into one place from multiple sources and is constantly running checks in the background on that data. This means that the whole process of checking qualifications or work restrictions is automated so, a contractor with an out-of-date qualification, for example, will be flagged so the control room can plan effectively. It takes away all the time-consuming hand-cranking and constant checking and cross-referencing.

Mike Young, Senior Consultant – Offshore Wind, Sennen

By building a repository of centralised, reliable datasets of completed work, you can also track KPIs and get a full picture of turbine performance.

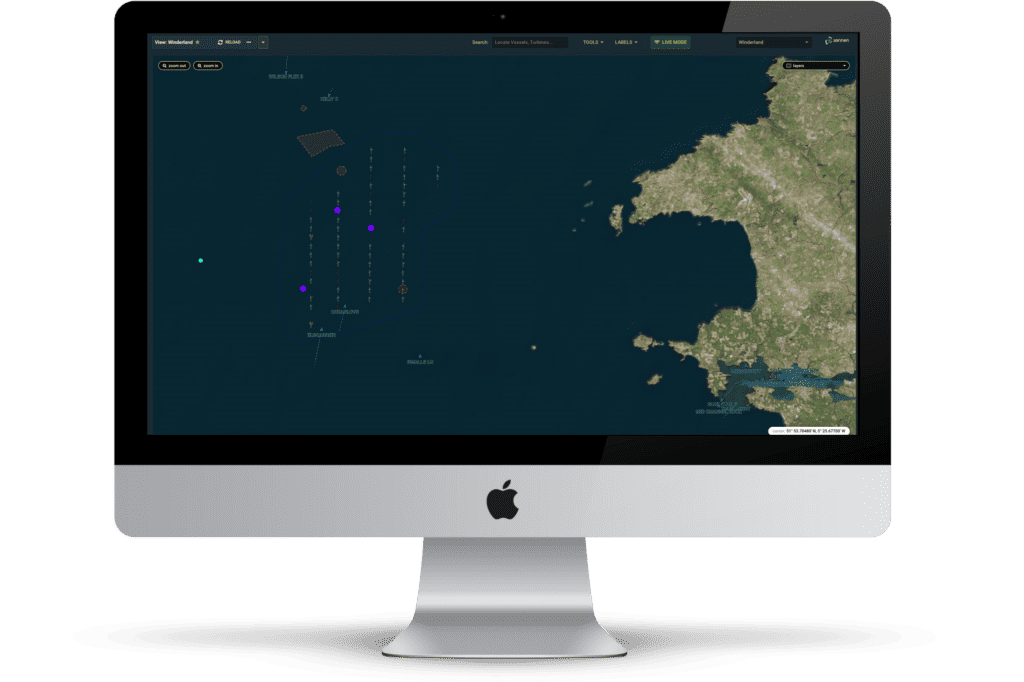

You can also monitor weather and tide windows alongside the movement of the team and see how work is progressing throughout the day. You can see where everyone is at any one time using an interactive marine map that tracks vessels, aircraft and people in real time.

The system really comes into its own when an operator has a sizeable wind farm – 30 turbines or more, or multiple sites. It’s something which an increasing number of operators need as more and more offshore wind farms come online – 2023 capacity additions are forecast to be 55 per cent higher than 2022 levels.

Mike Young, Senior Consultant – Offshore Wind, Sennen

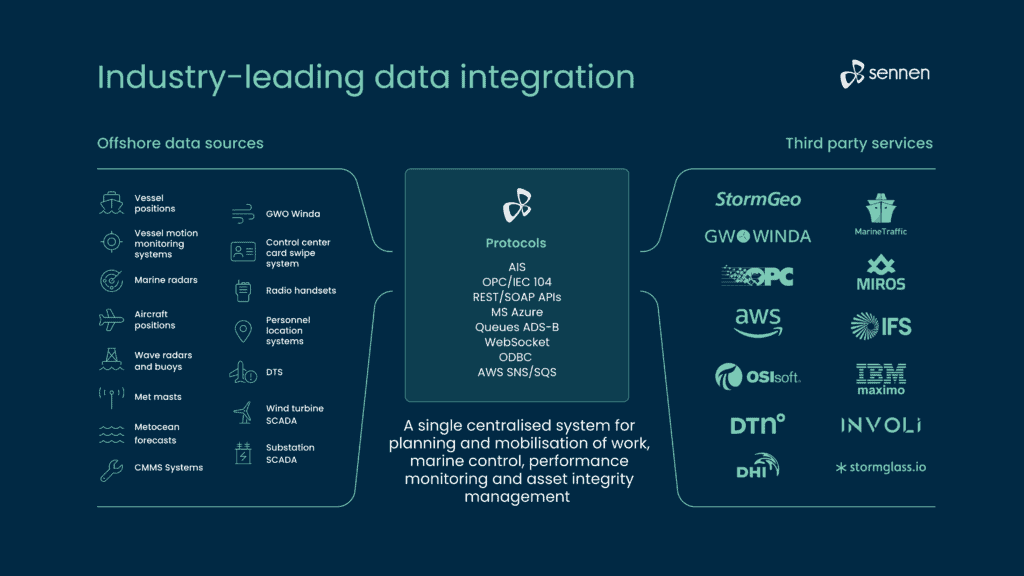

The data integration element is also really important as Sennen has been carefully designed so that it works alongside other systems, pulling in data from a wide variety of sources – including spreadsheets.

“It can integrate with pretty much anything so onboarding the software is easy, regardless of what you already have in place,” says Mike.

The system also comes pre-configured and our team works with operators to guide them through the process of embedding it. And, because it’s modular, you can just use certain elements to begin with and introduce it in stages. It can also be introduced site by site rather than across the whole portfolio in one go.

Mike Young, Senior Consultant – Offshore Wind, Sennen

Having seen first-hand how Sennen was a game-changer at London Array, Mike is now a huge advocate and wants other operators to reap the financial, operational and safety benefits.

Sennen’s Super Control Room is the most powerful, intuitive and sophisticated digital platform, designed specifically for the offshore wind industry. Changing traditional ways of working can feel difficult but operators won’t look back once they make the switch. In fact, I believe it’s something that must be done if operators want to scale up effectively.

Mike Young, Senior Consultant – Offshore Wind, Sennen